Key Features

- Horizontal double skinned integrally bunded construction

- Heavy duty 304L grade stainless steel inner tank with manway access

- Built in accordance with CAA guidelines for aircraft re-fuelling equipment

- Inspection hatch

- 5mm & 6mm thick S275 grade mild steel outer bund. 110% tank capacity

- Double broad cradle base with 1:40 angled fall to sump low point

- Lifting eyes suitable for lifting and moving empty tank

- Open fronted design for easy access to fuel dispenser, with rain peak and galvanised pump stand

- Premium extra cabinet with vented side entrance door giving access to filters, reel and offset fill line etc.

- Side cabinet with roller shutter door

- Fill point – 2” stainless steel with Self Climat OPD Overfill Valve DN50 type NT- Jet A1 / Avgas

- Normond analogue hydrostatic tank contents gauge

- 1” stainless steel sump draw line

- Shot blasted to SA 2.5 and painted in 2-pack polyurethane finish (standard White)

- Suitable for use with Avgas or Jet A-1

Standard Specification

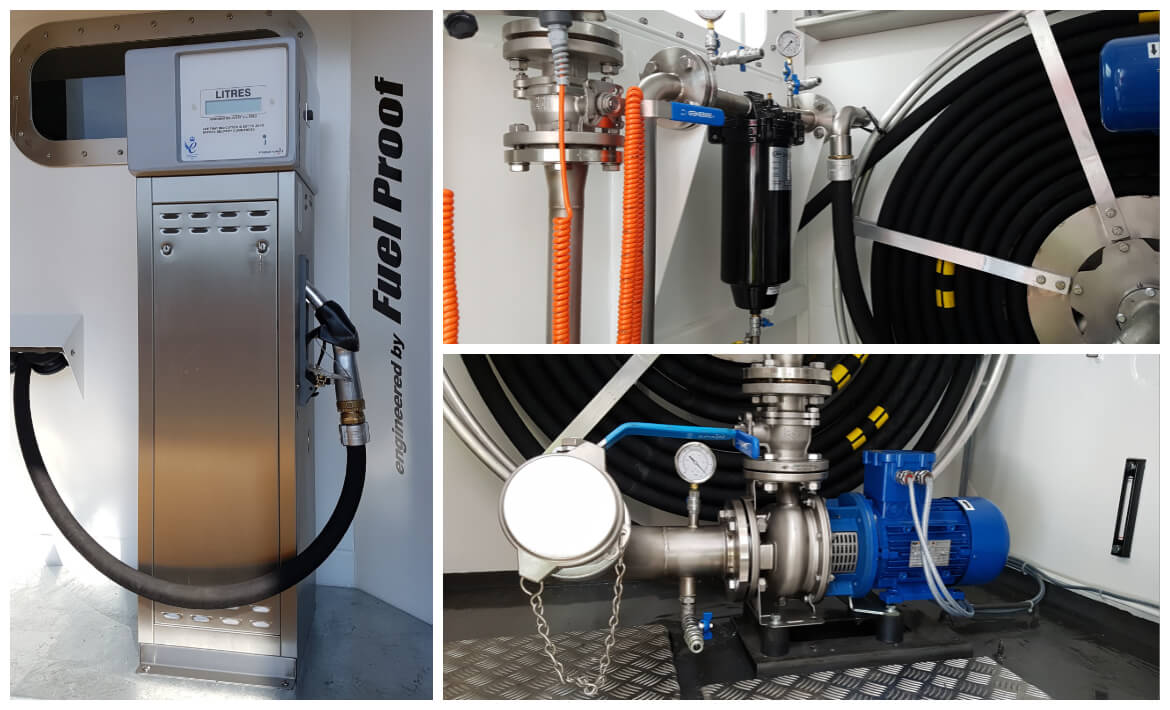

- Pumptronics Series C Commercial fuel dispensing unit with stainless steel body and digital readouts

80 to 90 litre/min flow rate*, ATEX Exd IIB T4 230V 50Hz motor. Approved by UK Weights and Measures.

Measuring Instrument Directive approved - Stainless steel pump internals with full air separation

- Dual Facet VF-22SB filter vessel tested to EI/API 1581 (5th edition). Differential pressure gauge & water drain

- FG-0-612-2 filter cartridge to EI/API 1583 (4th edition) (particle & water blocking, 0.5 micron)

- Facet CC-22-7 Coalescer Cartridge to API 1581 5th edition

- Fuel Proof hydraulic powered hose reel with 30m x 1” Elaflex HD25 hose to EN 1361, API 1529 C

- ZVF25 manual refuelling nozzle with removable fine mesh strainer, complete with earth lead and dust cap.

- 30m hand rewind earth bonding reel

- Fuel Proof fuel sampling, inspection and recovery system, with 4L Closed Circuit Sampler

- EX50 230V sump pump & return pump (fitted with return Facet VF-22SB filter vessel, complete with coalescer filter element)

Optional Extras

- Floating suction arm (recommended best practice) (50mm NB Sch 5 304L stainless tube)

- Self-loading pump, centrifugal stainless steel, 2.2kW 230V Exd IIB T3 motor

- Input filtration, EI 1590 Qualified 2 micron particle element, in stainless steel vessel

- Galvanised anti-slip staircase and manway access platform. Hand rail for easy & safe access, BS compliant. (incl. UK installation. Increases overall height by 1m approx. Customer to confirm compliance with site height restrictions).

- ATEX Zone 1 HDL 100 - Ex emb Fluorescent Luminaire IP66/67 T4/T5 Gas & Dust

- External area flood lights and mounting poles, with dawn to dusk light controller

- Dry break coupling on fill point (Jet A-1 type)

- Nozzle earth lead

- Nozzle dust cap (Please note that the fitting of this cap can interfere with the stowing of the nozzle in the holder)

Technical Information

Length |

8300 mm |

Width |

2600 mm |

Height |

3200 mm |

Empty Weight |

6000 kg |

Full Weight |

23430 kg |

Maximum Hose Length |

30 m |